Working outdoors or near traffic is risky if you cannot be seen. Accidents happen fast in low visibility. A reflective safety vest makes you stand out, keeping you safer.

The main features of a reflective safety vest include bright fluorescent background fabric for daytime visibility and retroreflective tape that shines brightly when hit by light at night. They are usually lightweight and adjustable for comfort.

Understanding these vests better helps choose the right one. We need to look at what they are, why colors matter, and the standards they meet. Let's explore these details so you can be sure you have the best protection. As someone who has been in this business since 2007, I know how crucial these details are for safety.

What is a reflective safety vest1?

Are you confused about what exactly a safety vest does? Choosing the wrong gear can put people in danger. Let's clarify what these important vests are.

A reflective safety vest is a piece of clothing worn over other clothes. It uses bright, fluorescent material2 and reflective stripes3. This makes the person wearing it easy to see, day or night.

Let's dive deeper into how these vests work. The main job of a safety vest4 is to make someone highly visible. This helps prevent accidents, especially "struck-by" incidents where vehicles hit workers. They achieve this in two main ways. First, the background fabric is usually a very bright, fluorescent color like yellow-green or orange-red. These colors react strongly to ultraviolet light from the sun, making them appear much brighter than normal colors during the daytime, dusk, and dawn. Second, the vest has strips of retroreflective material. This material doesn't glow on its own. Instead, it bounces light from sources like car headlights directly back towards the source. This makes the wearer appear very bright to drivers at night or in low light. Here at Vissafety, we focus on using quality materials that meet global standards to ensure this visibility works effectively, protecting workers and bringing peace of mind.

What do the colors of reflective vests mean?

You see vests in different bright colors on work sites. Are you unsure if the color choice matters for safety? Picking the wrong color might reduce visibility in certain conditions.

Vest colors mainly help wearers stand out against their work environment. Fluorescent yellow-green and orange-red are the most common for high contrast. Other colors like blue, green, or black often identify specific roles or teams.

The choice of color is not just about preference; it is about contrast and conspicuity (how easily something is seen). The most recognized standards, like ANSI/ISEA 107 in the US, specify fluorescent yellow-green, fluorescent orange-red, and fluorescent red as compliant options for the background material because they offer excellent visibility against most backgrounds.

Common High-Visibility Colors:

- Fluorescent Yellow-Green5: Offers superior contrast against complex urban and natural backgrounds, like foliage. It performs well in various light conditions.

- Fluorescent Orange-Red6: Stands out very well in daylight, open areas, and against snow. It is often preferred by road crews.

- Fluorescent Red: A newer option in ANSI standards, providing high visibility, especially during daylight.

Sometimes, other colors are used, but they might not meet specific high-visibility standards7 for traffic environments. These are often used for identification:

| Color | Common Use |

|---|---|

| Blue | Police, Emergency Medical Services (EMS) |

| Green | CERT teams, sometimes safety officers |

| Black/Grey | Often for specific roles, less common for HV |

| Pink | Sometimes used for events or specific causes |

At Vissafety, we offer vests in standard compliant colors and can customize colors for specific roles or branding needs, ensuring both safety and function.

What is the difference between orange and yellow reflective vests?

Choosing between an orange or yellow vest seems simple. But picking the one that offers less contrast for your environment is risky. Let's understand the key difference to make the right choice.

The primary difference lies in how they contrast with surroundings. Yellow-green generally provides better visibility against complex, darker backgrounds. Orange-red stands out well against lighter backgrounds, open sky, and snow during daylight.

Both fluorescent yellow-green and fluorescent orange-red are approved colors under major safety standards like ANSI/ISEA 107 because both provide excellent visibility. The best choice depends heavily on the specific work environment and lighting conditions. Yellow-green is often considered more versatile as it contrasts well against many natural and urban landscapes. Think about road work beside green trees or fields – yellow-green stands out clearly. Orange-red offers excellent contrast against bright conditions, like a sunny day on an open highway or against a snowy landscape where yellow might blend in more. Many road construction crews in North America favor orange-red. From my experience working with clients like Danny Cheng in California, who serves diverse sectors, having options in both colors is crucial. We ensure our vests in both colors meet strict compliance standards like ANSI/ISEA 107, giving clients the flexibility to choose the best option for their specific worker environments without compromising safety.

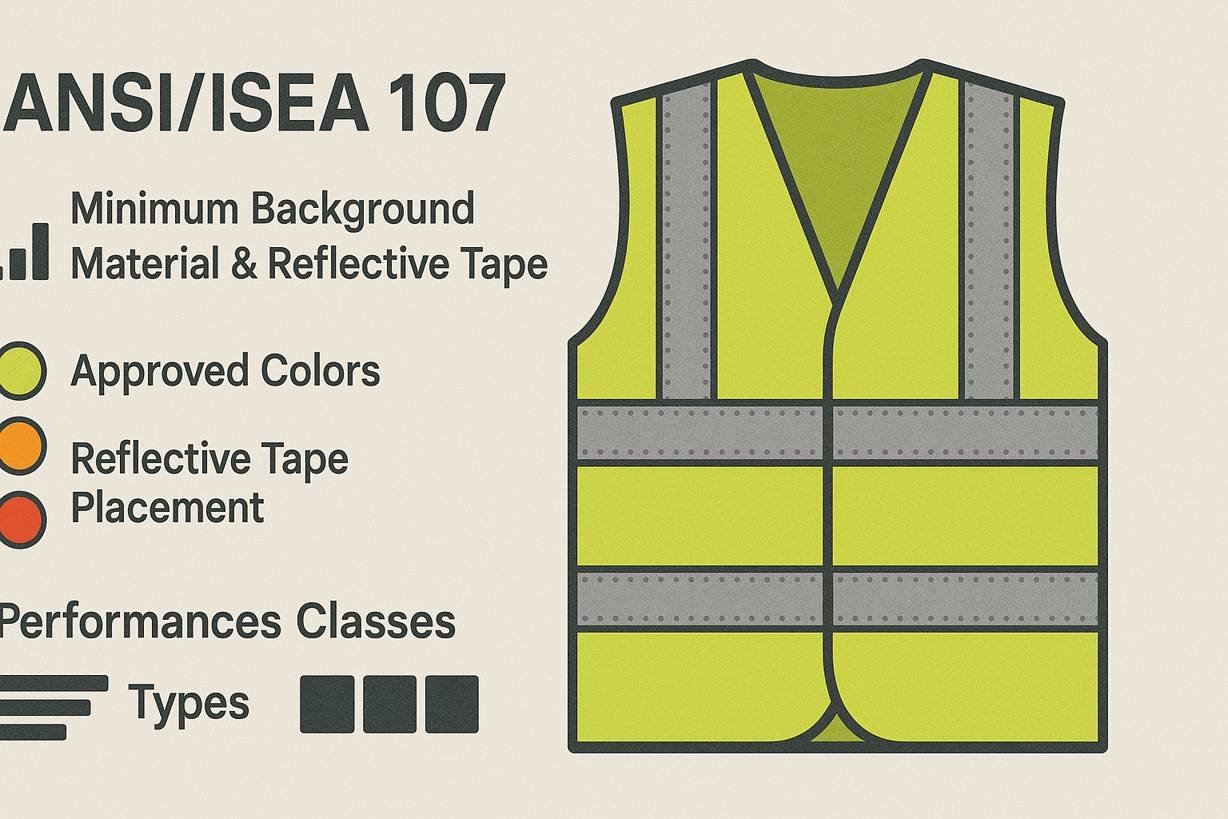

What are the ANSI standards for vests?

Need vests that meet safety regulations? Using non-compliant vests risks worker safety and can lead to penalties. It's vital to understand the standards they must meet.

The key standard is ANSI/ISEA 107. It sets minimum requirements for the amount of background material and reflective tape, specifies approved colors, and dictates tape placement. It defines Performance Classes and Types based on risk levels.

The ANSI/ISEA 107 standard is the American national standard for high-visibility safety apparel (HVSA). It's the benchmark many employers, including those needing OSHA compliance, look to. It categorizes garments into Performance Classes and Types.

Performance Classes:

These are based on the amount of visible materials and design attributes needed for different risk levels.

- Class 1: Minimum required visible material. For workers in lower-risk environments, away from traffic, or where speeds don't exceed 25 mph. (Example: Parking attendants).

- Class 2: More background material and retroreflective tape than Class 1. For workers near roadways where traffic exceeds 25 mph. (Example: Road construction workers, utility workers). This is the most common class for vests.

- Class 3: Highest level of visible material, often requires sleeves. For workers in high-risk environments, exposed to high-speed traffic, complex backgrounds, or bad weather. (Example: Highway flaggers, emergency responders).

Garment Types:

These relate to the expected work environment.

- Type O: Off-road environments (Class 1 only).

- Type R: Roadway environments (Class 2 or 3).

- Type P: Public Safety (Police, Fire, EMS) (Class 2 or 3), often includes features like shorter fronts for belt access.

Meeting these standards is non-negotiable for us at Vissafety. Our R&D lab and triple inspection process ensure every vest meets or exceeds ANSI/ISEA 107 requirements, giving clients like Danny the certified, reliable products they need.

What are the different types of reflective vests?

You know you need a vest, but there are so many styles. Feeling overwhelmed trying to pick the best design for your needs? Let's break down the common types available.

Common types include basic mesh vests for general visibility, surveyor vests with multiple pockets, breakaway vests designed to tear off if caught, and specialized vests like incident command or flame-resistant vests.

Beyond the basic function of visibility, different vest types offer features suited for specific jobs and hazards.

- General Purpose / Mesh Vests: These are often the simplest and most affordable. Usually made of lightweight polyester mesh for breathability, they provide basic ANSI Class 1 or 2 visibility. Good for general site workers, event staff, or visitors.

- Surveyor Vests: Designed for surveyors, engineers, or supervisors who need to carry tools and instruments. They feature multiple pockets (inside and outside), often including large plan pockets on the back, and may have mic tabs. They usually meet ANSI Class 2 requirements.

- Breakaway Vests: Crucial for workers around moving machinery or traffic where snagging is a hazard. These vests have hook-and-loop (Velcro) closures at the shoulders, sides, and front, allowing the vest to tear away safely if caught, preventing the worker from being pulled into danger. They typically meet ANSI Class 2 or 3.

- Incident Command Vests: Used by emergency responders to easily identify roles during an incident. They follow a standardized color-coding system (e.g., red for Operations Chief, blue for Logistics). Visibility standards still apply.

- Flame-Resistant (FR) Vests: Made from FR-rated materials for workers exposed to potential flame or arc flash hazards, often worn over other FR clothing. Must meet specific FR standards in addition to ANSI 107.

At Vissafety, we pride ourselves on offering a wide range, including unique styles and customizable options, ensuring we can meet the specific functional needs of diverse workforces.

What are the OSHA standards for reflective clothing?

Worried about meeting OSHA requirements for worker visibility? Failing to comply can result in fines and, more importantly, worker injuries. Let's clarify what OSHA expects regarding reflective clothing.

OSHA requires employers to protect workers from hazards, including being struck by vehicles. While OSHA doesn't have its own specific design standard like ANSI 107, it often references ANSI 107 as a way to comply with visibility requirements in relevant regulations (e.g., construction, road work).

The Occupational Safety and Health Administration (OSHA) sets and enforces standards to ensure safe working conditions. For high-visibility clothing, OSHA's requirements generally fall under a few key areas:

- General Duty Clause: Section 5(a)(1) requires employers to provide a workplace free from recognized hazards that could cause death or serious physical harm. Inadequate worker visibility near moving vehicles is a recognized hazard.

- Specific Regulations: OSHA has rules for specific industries. For example, the construction standard 29 CFR 1926.651(d) requires workers exposed to vehicular traffic to wear high-visibility garments. The Manual on Uniform Traffic Control Devices (MUTCD), incorporated by reference by OSHA for road work (29 CFR 1926.201(a)), mandates that workers exposed to traffic or construction equipment wear high-visibility safety apparel that meets ANSI/ISEA 107 Performance Class 2 or 3.

So, while OSHA might not detail the square inches of reflective tape needed, they mandate protection. Compliance often means adhering to the industry consensus standard, which is ANSI/ISEA 107. Employers must perform a hazard assessment8 to determine the appropriate level of visibility needed (which translates to the correct ANSI Class/Type). Providing workers with compliant Vissafety vests helps businesses meet these crucial OSHA obligations and protect their teams.

Conclusion

Reflective safety vests are vital PPE. They use bright fabrics and reflective tapes, meeting standards like ANSI 107, to make workers visible and safe day and night.

-

Understanding the function and benefits of reflective safety vests is essential for ensuring safety in various environments. Explore this link for detailed insights. ↩

-

Discover the significance of bright, fluorescent materials in enhancing visibility and safety for workers in hazardous conditions. ↩

-

Learn how reflective stripes enhance visibility and safety, especially in low-light conditions, making them crucial for protective gear. ↩

-

Understanding the purpose of safety vests can enhance workplace safety and awareness. Explore this link for detailed insights. ↩

-

Explore the advantages of Fluorescent Yellow-Green in enhancing visibility and safety in various environments. ↩

-

Learn why Fluorescent Orange-Red is favored for its visibility in daylight and open areas, crucial for safety. ↩

-

Understanding high-visibility standards is essential for ensuring safety in various work environments. ↩

-

Learning how to conduct a hazard assessment is essential for identifying risks and ensuring a safe working environment for employees. ↩