Worried about PPE stockouts and compliance headaches? These issues can disrupt operations and put your workers at risk. We offer a clear path forward.

Streamline your hi-vis supply chain by focusing on proactive procurement, using technology for tracking, and partnering with a reliable manufacturer. A structured approach manages inventory efficiently, ensures compliance with standards like ANSI/ISEA 107, and improves overall worker safety.

I've spent over a decade in this industry, helping clients build robust supply chains. One of my long-term partners, Danny Cheng, runs a major PPE distribution business in California. He learned the hard way that a weak supply link can be disastrous, once losing a huge sum due to quality issues from another supplier. Working with us at Vissafetywear, he has solved these problems. We built a system that ensures he always has the compliant, high-quality gear he needs, right when he needs it. Let me show you how you can achieve the same stability and peace of mind by focusing on a few key areas.

Why is it important to wear high-visibility clothing in certain workplaces?

Are your workers nearly invisible in hazardous areas? Low visibility leads to accidents, injuries, and costly operational downtime. There is a very simple fix.

High-visibility clothing is crucial because it makes workers easily seen by vehicle operators and colleagues, especially in low light, bad weather, or complex environments. This significantly reduces the risk of struck-by accidents1, protecting lives and keeping projects on schedule.

The core reason for wearing hi-vis gear is a principle called "conspicuity2." This just means making someone stand out from their background. For a road worker, the background is traffic, machinery, and asphalt. For a factory worker, it could be forklifts, racking, and other moving equipment. Without high-visibility apparel, the human eye can easily miss a person in these complex environments, especially at dawn, dusk, or in poor weather. This is where accidents happen. By providing gear with fluorescent material for daytime visibility and retroreflective tape for nighttime, you create a sharp visual contrast that grabs the attention of anyone operating machinery. This simple step is one of the most effective ways to prevent life-threatening injuries. It's not just a recommendation; it's a fundamental safety requirement in many industries.

High-Risk Work Environments

The need for hi-vis clothing is critical in any setting where workers are exposed to moving vehicles or equipment.

| High-Risk Environment | Primary Hazard |

|---|---|

| Road Construction Zones | Passing cars, trucks, construction vehicles |

| Warehouses & Factories | Forklifts, pallet jacks, automated machinery |

| Airports & Railyards | Planes, luggage carts, trains, service vehicles |

| Emergency Services | Oncoming traffic at incident scenes |

| Utility & Telecom Work | Public road traffic, work vehicles |

Ultimately, wearing hi-vis gear is a non-negotiable part of a proactive safety culture3. It is the first line of defense in making your most valuable asset—your people—seen and safe.

What are the OSHA rules4 for Hi Vis?

Are you confused by the complex regulations for hi-vis clothing? Getting it wrong can lead to heavy fines and, more importantly, put your team in danger.

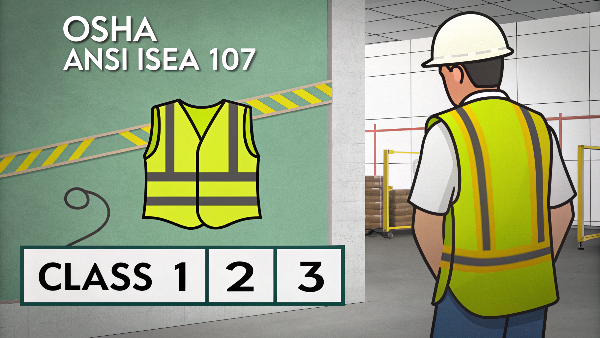

OSHA requires high-visibility apparel for workers exposed to vehicle traffic, like in road construction zones, under its rule 23 CFR Part 634. This rule mandates that the apparel must meet the ANSI/ISEA 1075 standard for performance class6 and garment type.

Many of our clients, especially those in the US like Danny, find navigating these rules challenging. The key thing to understand is that OSHA doesn't have its own detailed hi-vis standard. Instead, it points to other established regulations. The most important one is the Federal Highway Administration's 23 CFR Part 634, which makes the ANSI/ISEA 107 standard mandatory for all workers on federal-aid highways. This has become the accepted best practice across all industries where workers are near moving traffic. As a manufacturer, we build all our products to meet or exceed these standards, ensuring our clients are always compliant. We have an in-house lab with over 75 testing devices to verify that our materials meet color, luminosity, and durability requirements.

Understanding ANSI/ISEA 107 Classes

The ANSI/ISEA 107 standard classifies garments based on the amount of background and reflective material they have, which corresponds to the risk level of the work environment.

| Performance Class | Description & Use Case | Min. Background | Min. Reflective |

|---|---|---|---|

| Class 1 | For low-risk areas with slow-moving traffic (under 25 mph) and ample separation from traffic. Example: parking lot attendants. | 217 in² | 155 in² |

| Class 2 | For medium-risk areas with traffic speeds over 25 mph. Required for workers who need greater visibility. Example: roadway construction, utility work. | 775 in² | 201 in² |

| Class 3 | For high-risk areas with fast-moving traffic (>50 mph) and poor sight lines. Offers the highest level of visibility. Example: highway workers, emergency responders. | 1240 in² | 310 in² |

Choosing the right class is not optional. It is a critical step in ensuring worker safety7 and meeting your legal obligations under OSHA.

How do you ensure consistent use and compliance with PPE among factory workers?

Do workers sometimes forget or even refuse to wear their assigned PPE? This non-compliance undermines all your safety investments and supply chain planning8, creating serious risks.

To ensure compliance, you must combine clear policies with consistent training on why PPE is necessary. Make supervisors accountable for enforcement and, crucially, provide comfortable, well-fitting gear that workers don't mind wearing all day.

Providing the gear is only the first step. Getting people to wear it, day in and day out, is the real challenge. The most common reason for non-compliance I hear from clients is discomfort. If a safety vest is bulky, scratchy, or doesn't breathe, workers will find reasons not to wear it. That's why we focus on using modern, lightweight, and breathable fabrics. We also offer a wide range of sizes and styles, because one size does not fit all. When Danny needed a solution for workers in hot California summers, we co-developed a lightweight mesh jacket that met ANSI standards without adding heat stress. Wear rates went up immediately. Another powerful tool is customization. Adding a company logo fosters a sense of team identity and pride, turning a piece of mandatory equipment into part of a professional uniform.

A Framework for PPE Compliance

Your approach to compliance should be structured and continuous. It's not a one-time event.

| Strategy | Key Actions |

|---|---|

| 1. Clear Policy | Write a simple, non-negotiable rule: "Hi-vis must be worn in designated areas." Communicate it everywhere. |

| 2. Meaningful Training | Go beyond rules. Show videos of near-misses. Explain how hi-vis breaks down light to make them seen. |

| 3. Invest in Comfort | Survey workers on what they like and dislike. Offer options for different seasons. Prioritize fit and fabric. |

| 4. Supervisor Accountability | Make daily PPE checks part of the supervisor's official duties. They must lead by example and enforce the rules consistently. |

By treating compliance as a system that includes policy, training, quality gear, and accountability, you create a culture where safety is automatic.

Conclusion

A streamlined hi-vis supply chain9 combines smart procurement with quality, compliant gear. This ensures your workers are always protected and your operations run smoothly with no interruptions.

-

Find out how to minimize the risk of struck-by accidents with proper safety measures. ↩

-

Learn about the principle of conspicuity and its role in preventing workplace accidents. ↩

-

Discover strategies to build a proactive safety culture within your organization. ↩

-

Understand OSHA regulations to ensure compliance and protect your workforce. ↩

-

Get insights into the ANSI/ISEA 107 standard and its significance for worker safety. ↩

-

Get detailed information on performance classes and their applications in safety gear. ↩

-

Explore effective strategies to enhance worker safety and reduce accidents. ↩

-

Explore best practices to enhance your supply chain planning and operational efficiency. ↩

-

Discover how optimizing your hi-vis supply chain can enhance safety and efficiency. ↩