Are you confused by the different safety vest colors on a job site? This confusion can impact safety. Here is a simple guide to understanding what each color means.

Yes, safety vests are often color-coded1 by companies to define specific roles. While official ANSI/OSHA standards2 focus on visibility with fluorescent orange-red3 and yellow-green4, many worksites assign colors like blue, red, or black to managers, visitors, or specific teams for quick identification.

The aorld of safety vests goes beyond just the standard bright colors. While official regulations from bodies like OSHA set the baseline for what makes a vest safe for visibility5, many companies have built their own systems on top of that foundation. This internal color-coding is crucial for large, busy worksites where knowing who is who at a glance can prevent accidents and improve efficiency. Let's explore what these different colors mean and which ones are officially compliant. Understanding this helps everyone stay safer and more organized on the job.

What do the different colors of safety vests6 mean?

Seeing a rainbow of vests on a job site can be confusing. Not knowing the code can slow down communication. Knowing what each color means makes the workplace safer for everyone.

Different safety vest colors typically signify specific roles defined by a company. Standard fluorescent orange and yellow/lime green are for general high visibility. Other colors are assigned by individual worksites to identify personnel like managers, safety officers7, new workers8, or emergency responders9.

While ANSI/ISEA 107 doesn't assign meanings to colors, a general industry practice has emerged. It’s a simple system that helps organize large teams. For my client, Danny Cheng, this is a big deal. His customers in construction and logistics need clear ways to identify team leaders and new hires instantly. A new worker in a green vest, for example, can be easily spotted and helped. We at Vissafety produce a full spectrum of colors to help clients like Danny implement these custom safety plans10. A designer like Jacky might even specify a certain color for a company's uniform to match their branding while keeping role distinction clear.

Here is a common breakdown, but remember to always check your specific worksite's safety plan:

| Vest Color | Common Meaning |

|---|---|

| Fluorescent Orange | General worker, road crews, construction. High visibility5 against urban environments. |

| Fluorescent Yellow/Lime | General worker. Highest visibility in low-light conditions. |

| Blue | Technical staff, engineers, surveyors. |

| Red | Safety officers, fire wardens, emergency personnel. |

| Green | New workers, trainees, safety representatives11. |

| White/Gray | Site managers, supervisors, architects. |

| Black | Supervisors, management (often not ANSI-compliant for visibility). |

| Pink | Visitors, event staff (often not ANSI-compliant for visibility). |

What are the rules for safety vests?

OSHA rules can seem complex and difficult to follow. Getting them wrong can lead to fines and, more importantly, unsafe conditions. Let's break down the essential rules in a simple way.

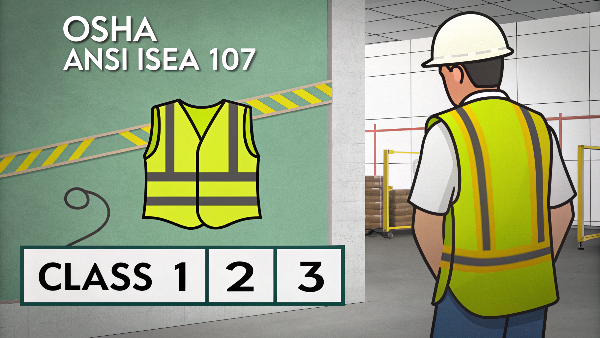

The main rule from OSHA and ANSI/ISEA 107 is about visibility. A compliant vest must use a specific fluorescent background color (yellow-green4, orange-red, or red) and have a minimum amount of retroreflective tape12. The Class (1, 2, or 3) depends on the job's risk level.

The ANSI/ISEA 107 standard is the key document here. It doesn't just say "be bright." It gives exact requirements for how much fluorescent material and reflective tape a vest needs to be classified for different risk levels. When I work with Danny, he emphasizes that his North American clients absolutely cannot compromise on compliance. They face strict regulations. That's why our factory has its own advanced lab to test every batch of fabric and tape. We make sure every Class 2 or Class 3 vest we ship meets or exceeds the standard. This gives Danny peace of mind, knowing he won't face recalls over quality issues like he did with a previous supplier.

Here’s a simple table explaining the classes:

| ANSI/ISEA 107 Class | Environment / Use Case | Required Fluorescent Material | Required Reflective Tape |

|---|---|---|---|

| Class 1 | Low-risk, low-speed traffic (e.g., parking attendants). | 217 in² | 155 in² |

| Class 2 | Higher-risk, roadway work, inclement weather. | 775 in² | 201 in² |

| Class 3 | Highest-risk, high-speed traffic, complex backgrounds. | 1240 in² | 310 in² |

Are pink safety vests13 OSHA approved?

Have you seen pink vests and wondered if they are compliant? Choosing a non-standard color might look good, but it could put you at risk of non-compliance. Let's get clear on this.

No, pink safety vests are generally not OSHA or ANSI/ISEA 107 compliant for high-visibility requirements. The standard approves only fluorescent yellow-green, orange-red, and red as background colors. Pink is often used for visitor identification or events in low-risk areas.

The reason is simple science. The approved fluorescent colors are chosen because they are the most conspicuous to the human eye against the widest range of natural and man-made backgrounds. They reflect more visible light than they absorb, making them appear to glow, especially at dawn and dusk. Fluorescent pink does not meet this specific visibility requirement. However, that doesn't mean they have no purpose. We often get requests for pink vests for large public events, charity runs, or to identify visitor groups on a controlled site. We can easily produce these, but we always consult with our clients, like Danny, to ensure they understand these are for identification purposes, not for use in high-risk environments where ANSI compliance is legally required.

Are black safety vests14 OSHA approved?

A black safety vest might look professional, but is it safe? Using a vest that isn't highly visible in a high-risk area is a major hazard. Let's look at where black vests fit in.

Black safety vests are not OSHA or ANSI/ISEA 107 compliant for high-visibility purposes because black does not provide conspicuity. They are often used by management or security in low-risk areas, relying on attached reflective tape for some nighttime visibility.

Black absorbs light instead of reflecting it, making it the opposite of what you need for daytime visibility. So, a solid black vest can't be ANSI compliant. However, you'll still see them on job sites. They are often worn by supervisors or foremen to distinguish them from the general workforce. Their role may not require them to be in the direct line of traffic. A more practical and compliant option we've developed is the "black bottom" vest. A product designer like Jacky would appreciate this design. The top portion is fully compliant fluorescent orange or yellow-green, while the lower portion is black. The black part helps hide dirt and grease in a high-contact area, making the vest look cleaner for longer while still meeting ANSI standards. This is an innovation that solved a real problem for Danny's clients.

What does a pink safety vest mean?

You might see a pink vest on a job site and wonder about its meaning. This unusual color can leave you guessing about that person's role. Let's decode its purpose.

A pink safety vest has no official meaning under ANSI/OSHA standards. Its meaning is determined by the specific company or event. It is most commonly used to distinguish visitors, volunteers, or staff at a special event from the primary workforce.

Because pink is not an ANSI-compliant color, its use is purely for identification. A worksite manager might order a small batch of pink vests for a group of architects or investors touring the site. This makes it instantly clear to every equipment operator that these individuals are visitors and may not be familiar with the site's dangers. It’s a simple visual cue that says, "be extra careful around this person." We at Vissafety can easily handle these small, custom-color orders. This flexibility is important for Danny, as it allows him to serve all his clients' needs, from large-scale compliant orders to small, specific requests for visitor management or corporate events. We help him provide a complete solution.

What does a purple safety vest mean?

Finding a purple safety vest on-site is rare. This non-traditional color can make you wonder what specific role that person plays. Let's explain this uncommon choice.

A purple safety vest has no standardized meaning under OSHA or ANSI rules. Like other non-compliant colors, its meaning is set by the company's internal safety plan. It can be used to identify a specific team, a certain subcontractor, or even for branding purposes.

Purple is another example of a color used for organizational purposes rather than for compliance. On a very large project with multiple companies working at once, a project manager might assign a different color to each contractor's team. One team might wear green, another blue, and another purple. This makes it incredibly easy to see who is working where and for which company. It simplifies logistics and accountability. For Vissafety, providing this level of customization is a core part of our business. We empower our clients, like Danny, to offer these tailored safety solutions. It allows his customers to build a more organized and visually intuitive worksite, which ultimately leads to a safer environment for everyone involved.

What are the colors for OSHA safety shirts15?

You may wonder if safety shirts follow the same color rules as vests. Proper color is critical for compliance and safety. Let’s clarify the official OSHA-approved colors for high-visibility shirts.

OSHA references the ANSI/ISEA 107 standard for high-visibility apparel16, which includes shirts. The only approved background colors are fluorescent yellow-green, fluorescent orange-red3, and fluorescent red. These colors ensure the wearer is visible against most backgrounds in daylight.

The rules for safety T-shirts are the same as for vests. The goal is conspicuity—making the worker stand out. Whether it's a vest, shirt, or jacket, if it's meant to be high-visibility PPE, it must be made in one of the three approved fluorescent colors. As a manufacturer, we source and test these specific fabrics constantly. When Danny's clients need safety shirts for warmer weather, he knows our products will be fully compliant. We've even developed cooling fabrics that meet ANSI color standards, providing both safety and comfort. This commitment to both compliance and innovation is why our 12-year partnership has been so successful. We don't just sell products; we solve problems.

What are the OSHA color codes?

Are you trying to understand OSHA's overall color system? The agency uses specific colors for more than just vests. Knowing this code is key for overall workplace safety and hazard communication.

OSHA has a standard color-coding system for marking physical hazards. For example, red indicates fire protection equipment and danger. Yellow signals caution and physical hazards. These colors are for workplace signs and markings, separate from the ANSI standard for high-visibility clothing.

It's important to distinguish between the two systems. The ANSI/ISEA 107 standard is specifically for high-visibility clothing to make people visible. OSHA's color code (standard 1910.144) is for marking pipes, aisles, and safety equipment to communicate hazards in the environment itself. A designer like Jacky, who works on industrial products, needs to be aware of both. While my company, Vissafety, focuses on the clothing aspect, we understand the entire safety ecosystem our clients operate in. Our expertise helps Danny advise his customers on creating a comprehensive safety plan where compliant apparel and proper hazard markings work together seamlessly.

Here is a simplified table of the OSHA color code for a quick reference:

| Color | General Meaning | Examples |

|---|---|---|

| Red | Danger, Stop, Fire Protection | Emergency stop buttons, flammable liquid cans, fire extinguishers. |

| Orange | Warning | Machine parts that can crush or cut, exposed edges. |

| Yellow | Caution | Tripping hazards, "wet floor" signs, material handling equipment. |

| Green | Safety | First aid kits, safety showers, emergency eyewash stations. |

| Blue | Information | "Out of Order" signs, informational notices. |

| Black/White | Traffic & Housekeeping | Aisle markings, traffic lanes, direction signs. |

What is the meaning of black safety vest?

You might see supervisors wearing black vests and wonder about their purpose. A black vest does not scream "safety," so what does it signify? Let's clarify the role of this vest.

A black safety vest typically signifies a management or supervisory role on a worksite. It is not an ANSI/ISEA 107 compliant color for high visibility. Its purpose is role identification, not to make the wearer conspicuous in high-traffic or low-light conditions.

The choice of a black vest is often about authority and differentiation. It sets a supervisor apart from a crew in orange or yellow vests. Because it provides no daytime visibility, it should only be worn in environments where the risk of being struck by moving vehicles or equipment is very low. Even then, these vests almost always feature retroreflective tape to provide some visibility in the dark when hit by a light source. For clients who want this style, we often recommend our compliant black-bottom designs instead. They offer the professional look and dirt-hiding function of black while keeping the worker safe and compliant with a fluorescent upper half. It’s a smart compromise that prioritizes safety without sacrific

-

Exploring the reasons behind color-coding can help improve safety and efficiency on job sites. ↩

-

Learning about these standards is crucial for ensuring compliance and safety in the workplace. ↩

-

This color is essential for visibility; understanding its significance can enhance safety. ↩ ↩

-

This color is vital for high visibility; knowing its role can help in safety planning. ↩ ↩

-

Visibility is key to safety; understanding its impact can prevent accidents. ↩ ↩

-

Understanding the types of safety vests can enhance workplace safety and ensure compliance with regulations. ↩

-

Knowing the roles of safety officers can improve communication and safety on site. ↩

-

Identifying new workers quickly can enhance safety and support on the job. ↩

-

Understanding the roles of emergency responders is crucial for effective safety measures. ↩

-

Exploring custom safety plans can improve organization and safety on job sites. ↩

-

Knowing the role of safety representatives can enhance safety culture and compliance. ↩

-

Reflective tape is crucial for visibility; understanding its function can improve safety. ↩

-

Knowing the compliance of pink vests is important for safety in high-risk areas. ↩

-

Understanding the role of black vests can clarify their use and safety implications. ↩

-

Knowing the approved colors for safety shirts is essential for compliance and visibility. ↩

-

Learning the definitions can help ensure compliance and safety in various environments. ↩