Struggling with low visibility dangers? Accidents often happen when people and objects are hard to see. Reflective tapes offer a bright solution, but are they truly effective?

Yes, reflective tapes are incredibly important for enhancing safety. They work by reflecting light directly back towards its source. This makes individuals and objects much more visible, especially in dark or low-light conditions, significantly reducing accident risks.

We all understand that safety is a top priority. Whether it's on a busy highway, a construction site, or even for personal use during a nighttime jog, being seen can be the difference between a close call and a serious incident. Reflective tapes are a simple yet powerful tool in our safety arsenal. Let's explore how these tapes work their magic and why they are so indispensable. At Vissafety, we've built our reputation on providing high-quality safety apparel, and a huge part of that is ensuring the reflective materials we use are top-notch.

What is the importance of reflective tape?

Low light conditions create hazards. People and equipment can become almost invisible. How does reflective tape1 combat this to prevent serious accidents?

Reflective tape is extremely important because it drastically improves visibility. By reflecting light, it alerts others to the presence of individuals or objects, preventing collisions and enhancing overall safety in numerous environments.

The primary importance of reflective tape lies in its ability to save lives and prevent injuries. Think about it. When light from a vehicle's headlights, a flashlight, or any other source hits reflective tape, the tape doesn't just scatter the light. Instead, it uses a technology called retro-reflection2. This means it bounces the light directly back to the original light source. So, the driver or person holding the light sees a bright, clear signal.

This is vital in many situations:

- Road Safety: Vehicles, cyclists, and pedestrians become much more visible at night.

- Workplace Safety: Workers in construction, logistics, and emergency services are protected, especially in low-light or complex environments. I've seen firsthand how our clients, like Danny Cheng who supplies safety gear to North American construction sites, emphasize the need for compliant reflective tapes. His business depends on keeping workers safe.

- Personal Safety: Joggers, children walking to school, or anyone out in the dark benefits.

At Vissafety, we understand this critical role. That's why we rigorously test every batch of reflective tape before it's used in our high-visibility clothing. We ensure it meets global standards like EN ISO 204713 and ANSI/ISEA 107. This commitment to quality means our clients receive apparel that truly performs when it matters most. The absence of effective reflective material can lead to tragic, preventable accidents. Its importance cannot be overstated.

| Area of Impact | How Reflective Tape Helps | Example Applications |

|---|---|---|

| Reduced Accidents | Makes users visible to motorists and machinery | Road work, construction sites, cycling |

| Enhanced Awareness | Alerts to hazards or boundaries | Barricades, emergency vehicles, pathways |

| Compliance | Meets legal and industry safety standards | Uniforms, vehicle markings, safety gear |

| Cost Savings | Prevents costly accidents and equipment damage | Fleet vehicles, industrial equipment |

What is the most visible reflective tape?

Not all reflective tapes are equal. Some shine brighter than others. Which type offers the absolute best visibility to keep you seen and safe?

The most visible reflective tapes are generally microprismatic tapes4. These offer higher reflectivity values compared to glass bead tapes, especially in wet conditions and at wider angles, making them superior for critical safety applications.

When we talk about the "most visible" reflective tape, we're usually referring to its coefficient of retroreflection5 (RA value). A higher RA value means more light is returned to the source, making the tape appear brighter. Generally, tapes fall into two main categories:

- Glass Bead Tapes: These use tiny glass spheres to reflect light. They are cost-effective and common. We use high-quality glass bead tapes that meet specific performance standards for many of our garments.

- Microprismatic Tapes: These use tiny, precisely arranged prisms. They are more efficient at reflecting light, especially over long distances, in wet weather, and at wider observation angles. These are often preferred for high-performance applications where maximum visibility is critical. For instance, Danny Cheng often inquires about our products using the latest prismatic technology for his clients who need top-tier visibility in demanding North American conditions.

The color of the tape also plays a role, which we'll discuss later. However, in terms of sheer reflective power, high-quality microprismatic tapes, particularly those in fluorescent colors like lime-yellow or orange, tend to be the most visible. At Vissafety, we carefully select the type of reflective tape based on the intended use of the garment and the specific standards it needs to meet, like ANSI/ISEA 1076. We always aim for the optimal balance of visibility, durability, and cost-effectiveness for our B2B clients.

| Tape Type | Reflectivity Level | Best For | Wet Performance | Angularity |

|---|---|---|---|---|

| Glass Bead | Good to Very Good | General workwear, fashion, budget-conscious | Moderate | Good |

| Microprismatic | Excellent | High-risk areas, EN ISO 20471, ANSI/ISEA 107 | Excellent | Excellent |

What is the purpose of a reflective sticker?

You see them on helmets, bikes, and machinery. Reflective stickers are small but mighty. What specific job do these adhesive safety markers perform?

The purpose of a reflective sticker is to enhance the visibility of smaller objects or specific points on larger items. They function like reflective tape but are often cut to shape for targeted application.

Reflective stickers serve much the same purpose as reflective tape: to increase visibility and safety in low-light conditions by reflecting light. The main difference often lies in their size, shape, and application. While tape is usually sold in rolls for linear applications, stickers are often die-cut into specific shapes or smaller pieces.

Here's why they are useful:

- Targeted Visibility: They can be placed on specific points that need to be seen, like the moving parts of machinery, a child's backpack, or the corners of a trailer.

- Curved Surfaces: Stickers can sometimes conform better to helmets or bicycle frames than a continuous strip of tape.

- Branding and Information: Reflective stickers can also incorporate logos or warning symbols, combining visibility with communication. As a manufacturer, Vissafety offers customization for reflective elements, and this can extend to stickers if a client has a specific need for their branded safety products.

- Versatility: They can be applied to a wide range of surfaces, from hard hats to outdoor gear.

I recall a project where we helped a client develop a line of safety accessories for recreational cyclists. Small, strategically placed reflective stickers on helmets and bike frames made a huge difference in their visibility tests. They are a simple, cost-effective way to add an extra layer of safety to items that might not accommodate full strips of reflective tape. The principle is the same: reflect light, be seen, stay safe.

| Feature | Reflective Tape | Reflective Sticker |

|---|---|---|

| Form | Rolls, strips | Pre-cut shapes, smaller pieces |

| Primary Use | Linear applications (garments, vehicles) | Targeted points, curved surfaces, branding |

| Customization | Width, length, color | Shape, size, color, printed designs |

| Application | Sewing, heat transfer, adhesive backing (rolls) | Adhesive backing (individual pieces) |

What are safety tapes?

The term "safety tape" sounds broad. It covers more than just reflective types. What exactly falls under this category of hazard-marking materials?

Safety tapes are a broad category of adhesive tapes used to mark hazards, delineate areas, or provide warnings. This includes reflective tapes, barrier tapes, anti-slip tapes, and floor marking tapes.

"Safety tapes" is a general term that encompasses various types of tapes designed to prevent accidents and enhance safety in different environments. While reflective tape is a prominent member of this family, it's not the only one. The common goal is to draw attention to potential dangers or to guide behavior.

Here are some common types of safety tapes:

- Reflective Tapes: As we've discussed, these make objects visible in the dark by reflecting light. We at Vissafety specialize in incorporating these into high-visibility clothing.

- Barrier Tapes (Caution/Danger Tapes): These are brightly colored, non-adhesive plastic tapes (e.g., yellow "Caution," red "Danger") used to temporarily block off hazardous areas.

- Floor Marking Tapes: Durable adhesive tapes used to mark pathways, aisles, storage areas, or hazardous zones on floors in warehouses, factories, and public spaces.

- Anti-Slip Tapes (Traction Tapes): These have a gritty surface to provide extra grip on stairs, ramps, and slippery surfaces, preventing falls.

- Hazard Warning Tapes (Striped Tapes): Often feature diagonal yellow-and-black or red-and-white stripes to indicate physical hazards or dangerous areas.

When we develop safety garments, the reflective tape we choose is a specific type of safety tape designed for maximum conspicuity. But for a facility manager or a safety officer, their toolkit of "safety tapes" would be much broader, addressing a wider range of potential risks. For example, Danny Cheng's clients in manufacturing facilities would use floor marking tapes and hazard warning tapes in addition to ensuring their workers wear high-visibility apparel with our reflective tapes.

| Type of Safety Tape | Primary Function | Common Colors/Patterns | Example Use |

|---|---|---|---|

| Reflective Tape | Enhance visibility in low light | Silver, fluorescent yellow/orange | Clothing, vehicles, signs |

| Barrier Tape | Temporarily restrict access | Yellow/Black, Red/White | Accident scenes, construction zones |

| Floor Marking Tape | Define pathways, zones | Solid colors (yellow, blue, red) | Warehouse aisles, social distancing markers |

| Anti-Slip Tape | Prevent slips and falls | Black, yellow, clear (gritty) | Stairs, ramps, wet areas |

| Hazard Warning Tape | Alert to physical hazards | Diagonal stripes (Y/B, R/W) | Low-hanging objects, edges of machinery |

What is the importance of a reflector?

Beyond tape, simple reflectors exist. From bikes to road posts, they shine. Why are these basic, light-bouncing devices still so crucial for safety?

The importance of a reflector lies in its passive ability to signal presence. It requires no power, yet effectively returns light to its source, making objects visible and preventing accidents, especially at night.

A reflector, in its essence, is any device or surface designed to reflect light. Reflective tape is a flexible form of reflector. The importance of any reflector, whether it's a plastic cat's eye on the road, a panel on a vehicle, or the tape on our Vissafety jackets, comes down to a few key principles:

- Passive Safety: Reflectors don't need batteries or an internal light source. They work by using the light available from external sources, like car headlights. This makes them reliable and low-maintenance.

- Enhanced Conspicuity: They make an object stand out from its background, especially in darkness or poor visibility conditions. This gives observers, like drivers, more time to react.

- Directional Warning: Retro-reflectors, the most effective kind for safety, send light directly back to the source. This means the person providing the light (e.g., a driver) gets the strongest signal.

I often think about the basic reflectors on bicycles or road marker posts. They are simple, yet they play a massive role in nighttime road safety. When we manufacture high-visibility clothing, the reflective tape acts as a series of powerful, flexible reflectors strategically placed on the garment. Our commitment to quality ensures these "reflectors" on our apparel perform exceptionally well, meeting standards that demand high retro-reflectivity. This dedication to effective reflection is something our long-term partners like Danny Cheng appreciate, as it directly impacts the safety of his customers. The core function – to bounce light back and make something seen – is simple but profoundly important.

Does reflective tape work in the dark?

It seems obvious, but let's clarify. If there's no light source at all, can reflective tape still do its job? How does it perform in complete darkness?

Yes, reflective tape works in the dark, but it requires an external light source to be effective. It reflects ambient light, like headlights or flashlights, making the taped object visible.

This is a common question, and the answer is nuanced. Reflective tape itself does not generate light. It's not like glow-in-the-dark material (photoluminescent) which absorbs light and then emits it slowly. Reflective tape is retro-reflective. This means it needs an external light source – car headlights, a streetlamp, a flashlight – to shine on it. When that light hits the tape, the tape then bounces a large portion of that light directly back towards the source.

So, in absolute, pitch-black darkness with no light source whatsoever, reflective tape will not be visible because there's no light for it to reflect. However, in most real-world "dark" scenarios where safety is a concern (like roads at night, or worksites with vehicle movement), there is almost always some form of light present, even if it's just distant headlights. Reflective tape is designed to capture and return this light very efficiently.

When we design garments at Vissafety, we consider these real-world conditions. The reflective tapes we use are chosen for their high performance in typical low-light and nighttime environments where vehicle or work lights are present. The tape makes the wearer stand out brightly when illuminated, which is precisely when it's needed most. So, while it doesn't "glow" on its own, it works exceptionally well in the dark when illuminated. This is a critical distinction.

| Condition | Reflective Tape Visibility | Explanation |

|---|---|---|

| Daylight | Visible (color contrast) | The tape's color is visible, some reflection may occur. |

| Low Light (Dusk/Dawn) | Highly Visible | Reflects available ambient and artificial light effectively. |

| Dark (with Light Source) | Extremely Visible | Excellently reflects light from headlights, flashlights, etc., back to source. |

| Total Darkness (No Light) | Not Visible | No light to reflect. |

What do the colors of reflective tape mean?

Silver, yellow, orange, even red. Reflective tapes come in various hues. Do these colors just look different, or do they signify specific meanings or uses?

Yes, the colors of reflective tape can have specific meanings or are chosen for optimal visibility in different conditions. For example, fluorescent yellow-green is highly visible in daylight and low light.

The color of reflective tape isn't just for aesthetics; it plays a significant role in visibility and sometimes even in conveying specific meanings, especially in regulated industries.

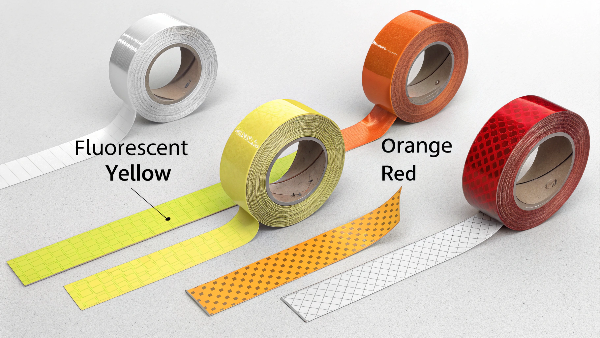

Here's a general guide to common reflective tape colors and their typical uses:

- Silver/White: This is one of the most common colors. It offers very high reflectivity and is widely used on safety clothing, vehicles, and signs. It provides excellent contrast against dark backgrounds at night.

- Fluorescent Yellow-Green (or Lime-Yellow): This color is extremely conspicuous during the daytime, dusk, and dawn. It also offers good reflectivity at night. It's a standard color for high-visibility safety vests (ANSI Class 2 and 3). We use a lot of this at Vissafety for our EN ISO 20471 and ANSI/ISEA 107 compliant garments.

- Fluorescent Orange-Red: Similar to yellow-green, this color offers excellent daytime visibility, especially against backgrounds like snow or foliage. It's also common for safety clothing and construction zone markings.

- Red: Often used on the rear of vehicles or to mark emergency exits or fire equipment. It has strong signaling power.

- Blue/Green/Other Colors: While less common for general high-visibility apparel, these might be used for specific identification purposes, on emergency service vehicles (blue for police), or for aesthetic reasons where high reflectivity is still desired but specific conspicuity standards aren't the primary driver.

When we select colors for our Vissafety products, we primarily focus on those that meet or exceed the chromaticity and reflectivity requirements of international standards. The goal is always maximum visibility for the wearer in their specific work environment. For instance, Danny Cheng's clients in construction often prefer fluorescent yellow-green or orange-red due to their superior daytime conspicuity on busy sites.

| Color | Primary Visibility Benefit(s) | Common Applications | Typical User Group(s) |

|---|---|---|---|

| Silver/White | High nighttime reflectivity | General safety apparel, vehicle markings, road signs | All industries, cyclists, pedestrians |

| Fluorescent Yellow-Green | Excellent daytime & low-light conspicuity, good nighttime | High-visibility workwear (ANSI/EN ISO 20471) | Construction, road crews, airport staff |

| Fluorescent Orange-Red | Excellent daytime conspicuity | High-visibility workwear, hunting gear, construction zones | Construction, utility workers, hunters |

| Red | Strong signal, rear marking | Vehicle rears, stop signs, emergency equipment | Transportation, emergency services |

| Blue | Specific identification (often) | Law enforcement vehicles, specialized equipment | Police, specific industrial |

How far away can you see reflective tape?

Visibility distance is critical for reaction time. Just how far away can a driver or observer spot someone wearing reflective tape, ensuring timely awareness?

Reflective tape can be seen from hundreds of feet away, often 500 feet (150 meters) or more, depending on the tape quality, light source intensity, and atmospheric conditions.

The distance from which reflective tape can be seen is a crucial factor in its effectiveness, as it directly relates to the reaction time available to an observer, like a driver. Several factors influence this visibility distance:

- Quality and Type of Tape: High-quality microprismatic tapes generally offer greater visibility distances than standard glass bead tapes because they return more light to the source. At Vissafety, our commitment to quality includes sourcing tapes with high retro-reflective values.

- Intensity of the Light Source: Brighter headlights will illuminate reflective tape from further away.

- Size and Placement of the Tape: Larger areas of tape, or tape placed strategically (e.g., in biomotion patterns that highlight human movement), will be detectable from greater distances. Our designs follow EN ISO 20471 and ANSI/ISEA 107 guidelines for placement.

- Atmospheric Conditions: Fog, rain, or snow can reduce visibility distance. However, good quality tapes are designed to perform well even in wet conditions.

- Angle of Observation: Retro-reflective tapes are most effective when viewed from close to the angle of the light source.

Generally, good quality reflective tape on a safety garment can make a person visible to a driver from distances of 500 feet (about 150 meters) or even further under optimal conditions. Some high-end prismatic tapes claim visibility up to 1000 feet or more. This is significantly further than a person in dark clothing (visible from perhaps 55 feet) or even light clothing (around 200 feet). This increased distance gives drivers several extra seconds of reaction time, which can be life-saving. I've heard from clients like Danny that this extended visibility is a key selling point for the safety gear he provides, especially in areas with high-speed traffic.

Is red reflective tape illegal?

You sometimes see red reflective tape on vehicles. But are there rules about where and how it can be used? Could using it improperly lead to trouble?

No, red reflective tape itself is not illegal. However, its use is often regulated. For example, on vehicles, red reflective tape is typically mandated or restricted to the rear or sides.

Red reflective tape is not inherently illegal, but its use is often regulated by specific laws and standards, particularly for vehicles and sometimes for safety signage or apparel in certain contexts. The key is how and where it's used.

For vehicles, regulations in many countries (like the DOT regulations in the US or ECE regulations in Europe) specify where different colors of reflective tape or reflectors should be placed:

- Red reflective tape/reflectors: Almost universally mandated for the rear of vehicles and trailers. This signals to following traffic that they are approaching the back of another vehicle.

- Amber/Yellow reflective tape/reflectors: Typically used for the sides of vehicles.

- White/Silver reflective tape/reflectors: Often permitted or required on the front sides or, in some cases, the front of trailers.

Using red reflective tape on the front of a vehicle, for instance, could be confusing and is generally prohibited because red at the front usually signifies an emergency vehicle or a warning light.

For high-visibility clothing, while fluorescent red-orange is a common and compliant background material color, solid red reflective tape (as the retroreflective material itself) is less common than silver or white for meeting standards like EN ISO 20471 or ANSI/ISEA 107, which focus on maximizing conspicuity through specific color and reflectivity performance. The standards often specify silver or similar high-efficiency retroreflective material combined with fluorescent background fabrics.

At Vissafety, when we design and manufacture garments, we strictly adhere to the relevant international standards which dictate the color and placement of reflective materials. We ensure our products are compliant for their intended markets, avoiding any issues of "illegal" or non-compliant use for our B2B clients. It's always best to check local regulations or specific industry standards if you're unsure about the application of colored reflective tapes.

| Vehicle Area | Common Reflective Tape Color Regulation | Purpose |

|---|---|---|

| Rear | Red | Indicates rear of vehicle, braking |

| Sides (Rearward) | Red or Amber (Yellow) | Indicates side profile |

| Sides (Forward) | Amber (Yellow) or White | Indicates side profile |

| Front | White (limited use, e.g., trailer front) | Generally not red to avoid confusion |

Conclusion

Reflective tapes are vital for safety. They boost visibility in low light. Choosing the right type and color, and ensuring quality, makes a huge difference in preventing accidents.

-

Explore how reflective tape enhances safety and visibility in various environments, potentially saving lives. ↩

-

Learn about retro-reflection technology and its crucial role in improving visibility and safety in low-light conditions. ↩

-

Discover the importance of EN ISO 20471 standards in ensuring the effectiveness of safety apparel and reflective materials. ↩

-

Explore this link to understand the technology behind microprismatic tapes and their superior visibility features. ↩

-

Learn about the coefficient of retroreflection to grasp how it affects visibility and safety in reflective materials. ↩

-

Discover the ANSI/ISEA 107 standards to ensure compliance and safety in reflective tape applications. ↩