Accidents plague worksites. Low visibility causes danger. Workers need better protection. This guide is your solution.

The ultimate guide to safety vests explains everything. It covers OSHA rules, ANSI standards, different vest classes, and what colors mean. It helps you pick the right vest for any job to keep people safe.

Understanding safety vests is very important for worker protection. We've seen many clients, like Danny Cheng from California, who rely on us for compliant and effective high-visibility gear. This guide breaks down complex rules into simple terms. We want to help you make informed choices for your team's safety, ensuring you meet all requirements. Keep reading to learn all about safety vests.

What is the OSHA rule for safety vests?

Jobsite safety can be confusing. Are you following OSHA rules for vests? Avoid fines and protect your workers properly.

OSHA requires employers to provide and use correct high-visibility safety apparel (HVSA)1. This is for areas where workers face risks from vehicles or construction equipment.

OSHA, the Occupational Safety and Health Administration, has rules to keep workers safe. For safety vests, there isn't one single rule that says "you must wear this specific vest." Instead, OSHA uses its General Duty Clause2. This clause says employers must provide a workplace free from known hazards that can cause death or serious harm. If poor visibility is a hazard, then high-visibility clothing becomes a requirement.

More specifically, OSHA's construction standards (29 CFR 1926) mention high-visibility garments for workers like flaggers or those exposed to public vehicle traffic or construction equipment. OSHA often refers to industry consensus standards like ANSI/ISEA 1073 to define what "appropriate" high-visibility clothing is. As a manufacturer, we at Vissafety ensure our vests meet these underlying expectations, helping businesses like Danny Cheng's stay compliant. It's about assessing the risk and providing gear that makes workers seen.

| Aspect | OSHA Guideline/Requirement | Implication for Employers |

|---|---|---|

| Hazard Assessment | Identify visibility risks for workers | Select appropriate HVSA for the risk |

| PPE Provision | Provide HVSA at no cost to employees | Ensure vests are available and fit well |

| Training | Instruct on proper use, care, and limits of HVSA | Keep records of worker training |

| Maintenance & Inspection | Ensure HVSA is kept in good condition | Replace vests that are damaged or faded |

| Compliance with ANSI | Often points to ANSI/ISEA 107 for performance specs | Choose ANSI-compliant vests for reliability |

What's the difference between Class 1, 2, and 3 safety vests4?

Picking the wrong vest class means danger. Workers might not be seen. Ensure your team has the right level of protection.

Safety vest Classes 1, 2, and 3 are set by ANSI/ISEA 107. They define how much bright background fabric and reflective tape a vest needs. This determines visibility for different work zones.

The ANSI/ISEA 107 standard is key here. It sorts safety vests5 into three main classes. This classification helps match the vest's visibility level to the worker's environment and risk. Class 1 vests are for low-risk areas. Think of parking attendants or warehouse workers far from traffic. They require the least amount of fluorescent background material and reflective tape.

Class 2 vests are for workers who need greater visibility in moderate-risk environments. This includes roadway construction workers where traffic is moving faster than 25 mph, or in bad weather. They need more visible material than Class 1.

Class 3 vests offer the highest level of visibility. They are for workers in high-risk situations. This includes high-speed traffic (over 50 mph), complex backgrounds, or when workers must be seen from a long distance, like emergency responders. These vests require the most background and reflective material, often including material on the sleeves. We help clients like Danny select the precise class for their teams, ensuring both safety and compliance across North America.

| Feature | Class 1 | Class 2 | Class 3 |

|---|---|---|---|

| Primary Use | Low-risk, off-road, workers separated from traffic | Moderate-risk, near roadways, bad weather | High-risk, high-speed traffic, complex backgrounds |

| Worker Speeds/Traffic | Traffic under 25 mph | Traffic over 25 mph | Traffic over 50 mph, very hard to see worker |

| Background Material (min) | 217 sq. in. (e.g., yellow, orange, red) | 775 sq. in. (if sleeved) / 540 sq. in. (vest) | 1240 sq. in. (if sleeved) / 852.6 sq. in. (vest) |

| Retroreflective Tape (min) | 155 sq. in. (1-inch width recommended) | 201 sq. in. (1.375-inch width recommended) | 310 sq. in. (2-inch width recommended) |

| Tape Configuration | Around torso, shoulder option available | Over shoulders, around torso | Over shoulders, around torso and sleeves (if present) |

| Typical Jobs | Parking staff, warehouse workers far from traffic | Road construction, utility crews, surveyors | Emergency teams, flaggers, highway workers |

What is the description of a safety vest?

What makes a vest a "safety" vest? Is any bright shirt enough? Understand the features that truly protect workers.

A safety vest is a special high-visibility garment. It uses bright fluorescent fabric for daytime and shiny reflective tape for nighttime. This makes the wearer easy to see, preventing accidents.

A safety vest is more than just a piece of clothing. Its main job is to make a person highly visible in all light conditions. This is achieved through two key components. First, the background material. This is usually a brightly colored fluorescent fabric, often yellow-green, orange-red, or red. Fluorescent materials react with UV light from the sun, making them appear to glow, especially during daytime, dawn, and dusk. This helps the wearer stand out against their surroundings.

Second, retroreflective material. This is usually tape or strips sewn onto the vest. This material doesn't create its own light. Instead, it reflects light from an external source, like car headlights, directly back towards that source. This makes the wearer very visible at night or in low-light conditions when a light shines on them. Besides these, safety vests often have practical features like pockets, mic tabs for radios, and secure closures like zippers or Velcro. At Vissafety, we focus on using durable, compliant materials for both the background fabric and reflective tapes, and we can customize designs to meet specific job needs.

| Component | Material Example | Purpose | Vissafety Focus |

|---|---|---|---|

| Background Fabric | Fluorescent Polyester | Makes wearer visible in daytime, dawn, dusk | High-quality, durable, colorfast fabrics |

| Retroreflective Tape | Glass bead, Microprismatic | Makes wearer visible at night by reflecting light | EN ISO 20471 & ANSI/ISEA 107 compliant tapes |

| Closures | Zipper, Velcro | Keeps vest securely on, easy to use | Strong and reliable options |

| Pockets & Features | Varies by design | Adds utility and convenience for tools, ID | Customization for specific job requirements |

What do the different color safety vests mean?

See many vest colors on a job site? Wonder if there's a special code? Colors can show roles or suit different environments.

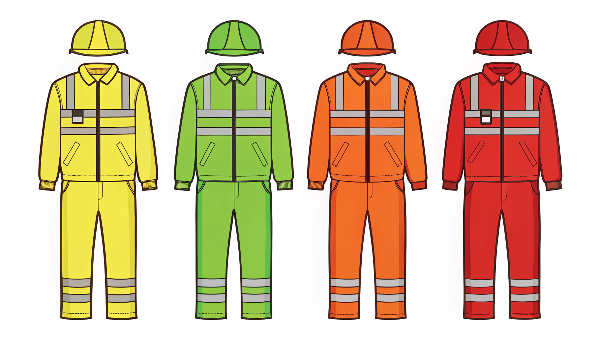

ANSI/ISEA 107 approves fluorescent yellow-green, orange-red, and red for true high visibility. Other colors like blue or black are often used for identification, not for regulated protection.

When it comes to safety vests that need to meet official standards like ANSI/ISEA 107, only a few colors are approved. These are fluorescent yellow-green, fluorescent orange-red, and fluorescent red. These colors are chosen because they are highly conspicuous against most natural and urban backgrounds, both in daylight and under artificial light. Yellow-green is very common and offers excellent contrast. Orange-red is particularly good against foliage or snowy backgrounds. Red is a newer addition and can be effective in urban settings.

However, you often see vests in other colors like blue, green, black, or even pink on work sites. These colors are generally not for meeting ANSI high-visibility requirements in hazardous zones. Instead, companies use them for identification. For example, visitors might wear blue vests, safety officers green, or supervisors black. While these vests can help differentiate roles, they don't offer the same level of certified visibility. Sometimes, these non-compliant colored vests will still have ANSI-compliant reflective tape to offer some nighttime visibility. We at Vissafety can produce vests in a wide array of colors, but we always guide our clients, like Danny, on which colors are compliant for specific safety needs versus those for identification.

| Color | Typical Non-Regulated Use/Association | ANSI/ISEA 107 Compliant? | Notes |

|---|---|---|---|

| Yellow-Green | Standard high visibility (ANSI compliant) | Yes | Most common, great contrast in many places |

| Orange-Red | Standard high visibility (ANSI compliant) | Yes | Good against trees, snow, and in complex work zones |

| Red | Standard high visibility (ANSI compliant) | Yes | Newest ANSI color, good in city areas, provides choice |

| Blue | Visitors, temporary staff, specific utility (e.g., water) | No | For telling people apart, not for traffic zones |

| Green (dark) | Safety officers, sometimes landscaping (non-traffic) | No | For telling people apart |

| Black | Supervisors, special teams, often has hi-vis tape | No | Can make hi-vis tape stand out, not for main visibility |

| Pink | Used for events, or by personal choice | No | Not for official high-visibility safety needs |

What do the different safety colors mean?

Colors give quick warnings. Green means go, red means stop. What about colors for safety clothes?

Safety colors give fast visual messages. Bright yellow-green and orange-red are key for high-visibility clothes, making workers stand out. Other colors show specific dangers or roles.

Safety colors are a universal language. Think of traffic lights: red for stop, yellow for caution, green for go. This concept extends to workplace safety, often guided by standards like ANSI Z535.1 Safety Color Code. In this system, red typically signals danger, emergency stop controls, or fire protection equipment. Orange indicates a warning, often for hazardous machine parts. Yellow means caution, pointing out physical hazards like tripping or falling risks. Green is for safety, such as marking the location of first aid kits or emergency exits. Blue is often used for informational notices, not directly safety-related.

When we talk about high-visibility safety apparel (HVSA), the approved colors—fluorescent yellow-green, orange-red, and red—are chosen for their conspicuity. Their job is to make the wearer unmissable, rather than signaling a specific type of hazard in the same way a red "Danger" sign does. The brightness and contrast of these HVSA colors are critical for preventing accidents by ensuring workers are seen by vehicle operators or equipment controllers. While other colors might be used on vests for identification as discussed before, the core ANSI-approved colors are all about maximizing visibility.

| Color | General Safety Meaning (ANSI Z535.1) | HVSA Meaning (ANSI/ISEA 107) | Example Use (General) | Example Use (HVSA) |

|---|---|---|---|---|

| Red | Danger, Stop, Fire equipment | High Visibility (day/night) | Emergency stop button | Class 2/3 Vest |

| Orange | Warning, hazardous parts | High Visibility (day/night) | Machine guards | Class 2/3 Vest |

| Yellow | Caution, physical hazards | High Visibility (day/night, yellow-green) | Wet floor sign | Class 1/2/3 Vest |

| Green | Safety, First Aid location | Not primary HVSA (sometimes for ID) | First aid station | ID Vest (non-compliant) |

| Blue | Notice, Information | Not primary HVSA (sometimes for ID) | "Employees Only" sign | ID Vest (non-compliant) |

Can you wear a different color vest?

Want a special color vest for your team? Is that okay? Know when non-standard colors are fine to use.

Yes, you can wear different color vests for identification if they are not for required high-visibility safety. For OSHA/ANSI compliance in risky areas, only approved bright fluorescent colors are allowed.

You can certainly wear vests in colors other than the ANSI-approved fluorescent yellow-green, orange-red, or red, but it depends on the situation. If the vest is purely for identification purposes in an environment where high-visibility protection is not mandated by a risk assessment or regulations, then other colors are perfectly acceptable. For example, a company might use blue vests for visitors, black for supervisors, or green for specific teams within a factory or warehouse where there's no significant risk from moving vehicles or equipment. Event staff in controlled, non-traffic areas also often use various colored vests for branding or role differentiation.

However, if workers are in an area that requires ANSI/ISEA 107 compliant high-visibility apparel – like near roadways, construction sites with heavy machinery, or anywhere OSHA mandates it – then only the approved fluorescent colors are suitable for the primary garment. Using a non-compliant color in such a zone would not provide the necessary level of visibility and could lead to safety risks and non-compliance issues. We at Vissafety can produce vests in many colors. For clients like Danny, we help distinguish when a custom color is fine for branding a particular team versus when strict ANSI compliance with approved colors is essential for high-risk roles.

| Scenario | Approved ANSI Colors (Yellow-Green, Orange-Red, Red) | Other Colors (Blue, Black, etc.) | Vissafety Recommendation |

|---|---|---|---|

| Roadway construction workers | Mandatory | Not as primary HVSA | Use ANSI Class 2 or 3 in approved colors. |

| Warehouse workers (low vehicle traffic) | Recommended (e.g., Class 1) | Possible for role ID | Assess risk; Class 1 often good. Other colors can identify roles. |

| Event staff (controlled, no traffic area) | Not mandatory | Yes, for identification | Choose based on branding; can add reflective tape for some pop. |

| Visitors on site (escorted, away from hazards) | Not primary HVSA if not in active hazard zones | Yes, for identification | Clearly mark as "Visitor"; keep them safe from hazard zones. |

What is the ANSI standard for safety vests?

Heard of ANSI, but not sure what it means for safety vests? This standard is very important. Understand its role.

The ANSI/ISEA 107 standard is the American National Standard for High-Visibility Safety Apparel. It details requirements for design, performance of materials, and how garments are classified (Class 1, 2, 3).

The full name is ANSI/ISEA 107 "American National Standard for High-Visibility Safety Apparel and Accessories." This standard is the backbone of safety vest regulation in the USA. It's developed by the American National Standards Institute (ANSI) and the International Safety Equipment Association (ISEA). Its main purpose is to provide clear guidelines for manufacturers like us, and for employers, on what makes a high-visibility garment effective.

The standard specifies several key things. It dictates the minimum amounts of fluorescent background material needed for daytime visibility and the minimum amounts of retroreflective material for nighttime visibility. It also covers the placement of these materials to ensure 360-degree visibility. Color specifications are very precise, defining the acceptable shades of yellow-green, orange-red, and red, along with their brightness. Beyond just visibility, ANSI/ISEA 107 sets performance requirements for the materials, like tear strength and colorfastness after washing or UV exposure. It also defines garment classifications (Class 1, 2, 3) and types (Type O for off-road, Type R for roadway, Type P for public safety) to match garments to different risk levels and work environments. Our Vissafety R&D lab, with its 75+ testing devices, ensures our products meet these strict criteria.

| Aspect Covered | Details | Why It's Important for Safety | Vissafety's Compliance Method |

|---|---|---|---|

| Background Material | Min. area, approved fluorescent colors (yellow-green, orange-red, red) | Provides visibility during daylight hours | Sourcing and testing compliant, vibrant fabrics |

| Retroreflective Material | Min. area, performance levels, placement for 360° view | Ensures visibility at night and in low light | Using certified tapes, designing for max reflection |

| Garment Classification | Class 1, 2, 3 based on material amounts for different risk levels | Matches protection level to the specific job hazard | Manufacturing vests to meet each class specification |

| Garment Types | Type O (Off-Road), R (Roadway), P (Public Safety) | Tailors garment needs to specific work environments | Offering diverse vest types for all client needs |

| Testing & Labeling | Rules for testing materials, care instructions, garment marking | Ensures consistent quality and informs the user correctly | Rigorous in-house lab testing, clear product labels |

Do class 3 vests have to have sleeves?

Class 3 gives the most visibility. Does this always mean it needs sleeves? Let's clarify this important design feature.

Not always. ANSI/ISEA 107 allows Class 3 compliance6 for sleeveless vests if they meet the higher minimum amounts for background and reflective material. However, sleeves add a lot to visibility.

This is a common question. While many Class 3 garments, like jackets or long-sleeved shirts, do have sleeves to help meet the high material requirements, it's not an absolute must for a vest to be sleeveless and still achieve Class 3. The ANSI/ISEA 107 standard focuses on the total minimum area of both background fluorescent material and retroreflective tape. For Class 3, these minimums are the highest: 1240 square inches of background material (if it includes sleeves that are part of the HVSA) and 310 square inches of retroreflective material.

If a sleeveless vest (Type R or P) is to be Class 3 compliant on its own, its torso portion must be large enough to provide at least 852.6 square inches of background material, plus the 310 square inches of tape. This is a lot of material for just a vest body, so such designs are less common than sleeved Class 3 garments. More often, overall Class 3 visibility for workers wearing a vest is achieved through an ensemble. For example, wearing a Class 2 vest combined with Class E high-visibility pants creates an outfit that meets Class 3 requirements. Sleeves on a garment significantly increase the surface area for high-visibility materials7, making it easier to see the wearer's full body outline and motion. We at Vissafety offer various Class 3 solutions, including sleeved options and Class E ensembles, to meet diverse needs like those of Danny Cheng's clients who face varied North American weather.

| Configuration | Sleeves? | Background Material (min sq. in.) | Retroreflective Material (min sq. in.) | Notes |

|---|---|---|---|---|

| Class 3 Garment (typical) | Yes (Short or Long) | 1240 (for entire garment including sleeves) | 310 | Most common; e.g., jacket, fully sleeved vest. Provides full arm visibility. |

| Class 3 Vest (sleeveless) | No | 852.6 (Type R or P Vest only, body of vest) | 310 | Less common as standalone; requires a very large vest body. |

| Class 2 Vest + Class E Pants | Vest: Usually No, Pants: N/A (legs) | Vest: 775 (Type R), Pants: 465 (for both legs) | Vest: 201, Pants: 109 | This combination (ensemble) meets overall Class 3 requirements. |

Conclusion

This guide helps you pick the best safety vest. Know the standards, classes, and colors. Keep your workers safe and compliant.

-

Understanding OSHA's requirements for HVSA is crucial for compliance and worker safety. Explore this link for detailed guidelines. ↩

-

The General Duty Clause is key to workplace safety. Learn more about its implications and how it affects safety regulations. ↩

-

ANSI/ISEA 107 sets the standards for high-visibility clothing. Discover its specifications to ensure compliance and safety. ↩

-

Learning about the differences between Class 1, 2, and 3 safety vests can enhance workplace safety by ensuring proper visibility and protection for workers. ↩

-

Exploring the types of safety vests can help you choose the right one for your specific work conditions and safety requirements. ↩

-

Understanding Class 3 compliance is crucial for ensuring safety in high-risk environments. Explore this link for detailed insights. ↩

-

Discover the types of high-visibility materials that enhance safety in various environments, ensuring you choose the right gear. ↩